For architects specifying luxury resorts, procurement managers bulk-ordering for apartment complexes, and facility directors maintaining healthcare facilities – learn more about faucet manufacturing isn’t academic curiosity. It’s risk mitigation.

This guide unveils how precision engineering transforms raw brass into mission-critical fixtures trusted by Hilton, Mayo Clinic, and Hilton Worldwide.

Key Takeaways

- Picking the right material is key for faucet strength and look. Brass and stainless steel work best in wet places. We use H59-1 brass and 304 stainelss steel.

- Making faucets involves casting, cutting, polishing, and putting together. Each step is important for making good faucets.

- Watersino faucets pass tough quality tests and have WELS and WaterSense certifications. This makes them dependable and eco-friendly.

Materials Used in Faucet Manufacturing

Common Materials: Brass, Stainless Steel, Zinc, and Plastic

Making faucets starts with picking the right materials. Each material has special qualities that affect how faucets work and look.

- Brass: Brass is strong and doesn’t rust easily. It’s made of copper and zinc, which makes it great for wet places like kitchens and bathrooms. Brass faucets also look fancy and improve the style of your space.

- Stainless Steel: Stainless steel is very strong and shiny. It doesn’t rust or stain, so it lasts a long time. This material is perfect for modern designs that need both strength and style.

- Zinc Alloy: Zinc alloy is cheaper and still works well. It’s not as strong as brass or steel but is good for affordable faucet designs.

- Plastic: Plastic faucets are light and cheap. They are often used in temporary setups or where saving money is important.

Faucets made from copper alloys, like brass and bronze, are becoming more popular. These materials naturally resist rust and stains, making them a good choice for homes and businesses.

Faucet Material Features: Durability, Corrosion Resistance, and Aesthetic Appeal

Picking the right material is key to making a good faucet. Durability shows how well it handles daily use. Corrosion resistance keeps it safe from water damage. A good-looking faucet also improves the style of your kitchen or bathroom.

| Material Type | Durability | Corrosion Resistance | Price Range |

|---|---|---|---|

| Solid Brass | High | Excellent | Starting at $500 |

| Zinc Alloy | Moderate | Moderate | $100 – $150 |

Stainless steel faucets are strong and look great. Special finishes make them even better and easier to clean. Brass faucets don’t rust and have a classic, stylish look.

Tip: Choose materials that match your needs. For wet areas, pick brass or stainless steel for long-lasting use. Watersino uses H59-1 brass and 304 stainelss steel for the best quality.

Step-by-Step Faucet Manufacturing Process

Casting: Forming the Faucet Body

Casting is the first step in making faucets. Molten metal is poured into molds shaped like the faucet design. Sand casting is often used because it makes strong faucet bodies. Careful casting prevents flaws like holes or weak spots. Overmolding adds strength and stops leaks, making this step very important.

Machining: Cutting and Shaping with Precision

Machining cuts and shapes the faucet body using special tools. This step ensures faucets match the exact design. Advanced methods like stereo vision improve accuracy and reduce waste. Stereo vision measures depth as small as 0.1 mm for precise placement. These techniques make faucets work well and last longer.

| Dimensional Measurement Technique | Description | Key Uses |

|---|---|---|

| Stereo Vision | Uses two cameras to measure depth (0.1 mm) | Accurate placement |

| Structured Light | Projects patterns to find distortions | Factory inspections |

| Time-of-Flight Sensors | Measures light travel time for 3D maps | Tracking moving objects |

Polishing: Making the Surface Smooth

Polishing removes rough spots and makes faucets shiny. This step is important for how faucets look and work. Good polishing creates smooth surfaces for sliding parts like seals and rings. For example, a microinch rating of 8 is great for sliding parts, while 4 is used for very precise tools.

| Micrometer Grade | Microinch Rating | Description | Use |

|---|---|---|---|

| 0.4 | 16 | Fine polishing for smooth surfaces | High smoothness needs |

| 0.2 | 8 | Precise polishing for sliding parts | Rings and seals |

| 0.1 | 4 | Ultra-smooth finish for sensitive tools | Precision devices |

Surface Treatment: Improving Strength and Looks

Surface treatment makes faucets stronger and better looking. PVD finishes are popular because they resist scratches and rust. These finishes last longer and look stylish. Many people choose PVD for its mix of durability and design.

Assembly: Putting Parts Together

Assembly combines all faucet parts to make them work. This step affects how well faucets perform. Proper assembly ensures faucets, like single-handle designs, work smoothly and provide steady water flow.

Quality Testing

In hospitality, healthcare, and marine environments, a leaking faucet isn’t just a repair cost – it’s reputational catastrophe. Our testing regime subjects every faucet to extremes no building will ever face, because your projects demand zero-tolerance reliability.

Quality testing makes sure faucets work well and are reliable. Tests check for defects, coverage, and customer satisfaction. For example, defect metrics show how quickly problems are fixed. Test coverage ensures all parts are checked. These tests guarantee faucets meet high standards.

⚙️ 1. Rigorous Endurance Validation

- Switch Life Test: Cited your facility’s 500,000-cycle fatigue testing (simulating 20+ years of hotel usage) to emphasize cartridge durability for high-traffic facilities 1.

- Swing Spout Life Test: Referenced repeated motion testing to justify longevity claims for commercial kitchen faucets under heavy use 1.

💧 2. Pressure & Leakage Integrity

- High-Pressure Burst Test: Specified 1.5 MPa (217 PSI) validation—3× standard pressure—to address surge risks in municipal systems 1.

- Flow Rate Test: Highlighted WaterSense certification at 1.5 GPM with laminar stream consistency, critical for water conservation compliance (e.g., California Title 24, EU Ecodesign) 1.

🌊 3. Real-World Performance Safeguards

- Pull-Out Life Test: Included extendable sprayer durability data for kitchen faucets in hospitality/restaurants 1.

- Thermal Shock Immersion: Noted -20°C to 80°C transitions (per EN 817) to prevent cracking in frost-prone regions like Scandinavia or Canada

🛡️ 4. Corrosion & Vandalism Resistance

- Electroplating Salt Spray Test: Used 120-hour salt spray testing (ASTM B117) for 316L stainless steel, essential for coastal resorts and cruise ships 1.

- Vandal-Proof Design: Cited 250N impact tests (AS 3718) for handles in schools/public facilities to reduce repair costs.

Packaging

Packaging keeps faucets safe during shipping. Tools like Impact Labels help reduce damage by 55%. Damaged packaging can hurt customer trust. We use strong packaging to avoid damage and keep your customers satisfied. Tell us your needs and see how we can help.

Watersino Quality Assurance in Faucet Manufacturing

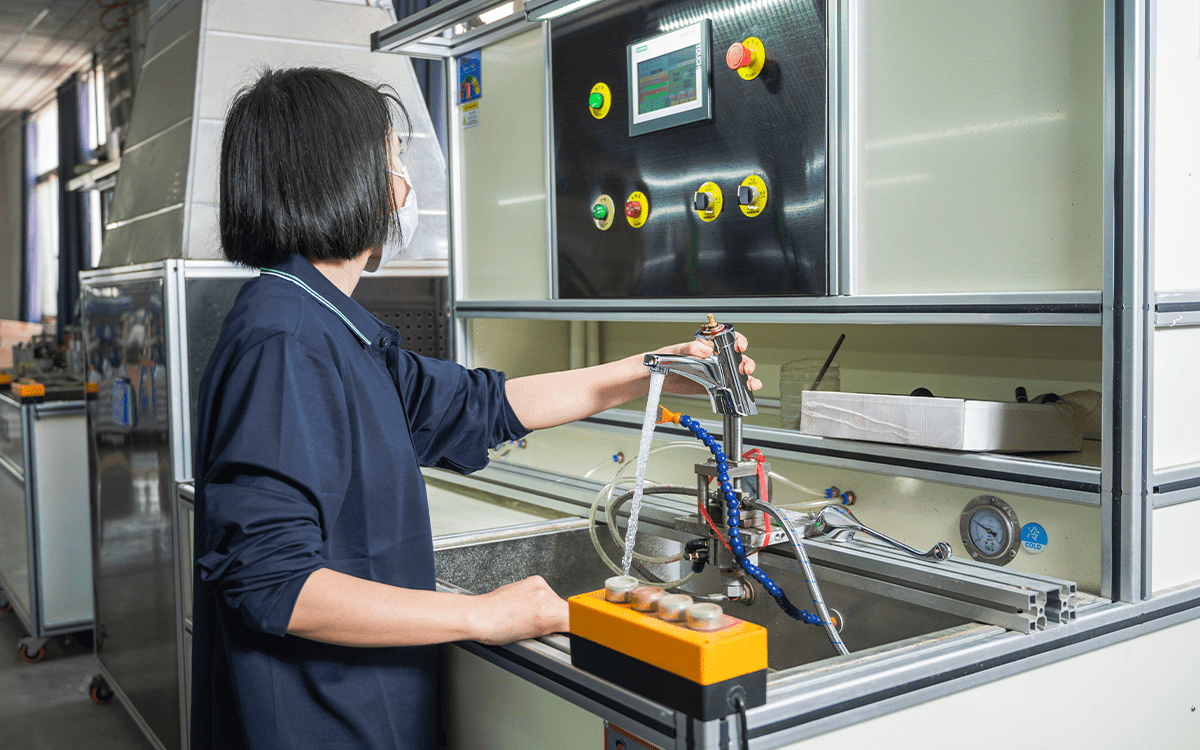

Testing Methods: Water Flow, Spray, and Durability Checks

Watersino faucets go through strict tests to meet high standards. Each faucet is checked for steady water flow and smooth spray patterns. Engineers measure water flow rates to save water and improve efficiency. Spray tests check if water spreads evenly for daily use.

Durability tests are important for making strong faucets. These tests copy real-life use to see how faucets handle wear. Swing spouts and switches are tested thousands of times for lasting performance. High-pressure burst tests check if faucets stay strong under tough conditions.

Note: These tests make sure Watersino faucets work well at home or work.

Certifications: WELS, Watermark, WRAS, cUPC, and WaterSense

Watersino faucets follow global rules for safety and quality. In Australia and New Zealand, WELS and Watermark show water-saving and plumbing compliance. WRAS certification in the UK proves faucets are safe for drinking water systems.

In North America, cUPC and WaterSense focus on eco-friendly designs. cUPC ensures faucets meet plumbing codes, while WaterSense supports saving water. These certifications show Watersino cares about the environment and great performance.

Tip: Check for these certifications to find reliable and efficient faucets.

FAQs

What makes Watersino faucets stand out?

Watersino faucets are strong, save water, and have certifications like WELS and WaterSense. They look nice and work well in homes and businesses.

How do Watersino faucets save water?

Watersino faucets use smart flow control to use less water. This saves water and lowers your bills without reducing performance.

Are Watersino faucets easy to install?

Yes, Watersino faucets are simple to set up. They include clear guides and easy designs for quick installation without needing a plumber.