This article investigates the most resilient finishes for commercial faucets. By examining coating technologies, industry testing standards, and real-world performance, we identify the solutions that truly endure. The findings reveal that scratch-resistant PVD (Physical Vapor Deposition) finishes, combined with robust anti-vandal fixtures, offer unparalleled longevity. The significance for facility managers, architects, and specifiers is clear: selecting the right heavy-use faucet coatings based on verified commercial durability testing is critical for reducing lifetime costs, maintaining aesthetics, and ensuring user satisfaction in demanding environments.

The choice of a faucet in a public restroom is a critical operational decision. In airports, stadiums, schools, and office buildings, fixtures are subjected to a level of abuse that consumer-grade products cannot withstand. The finish is the first line of defense, facing constant friction, impact, harsh chemicals, and intentional misuse. A worn, chipped, or stained finish projects an image of neglect and poor hygiene, directly impacting the perception of an entire facility. This article cuts through the marketing claims to explore the heavy-use faucet coatings that genuinely stand the test of time, delving into the technology behind them and the rigorous validation they must pass.

The Gold Standard in Durability: Scratch-Resistant PVD Finishes

When discussing finishes that last, PVD technology stands head and shoulders above traditional electroplating. PVD, or Physical Vapor Deposition, is a vacuum coating process that creates an exceptionally hard, durable, and uniform surface layer.

The Science of PVD Superiority

Unlike electroplated finishes, which sit on the surface, scratch-resistant PVD finishes are molecularly bonded to the brass or stainless steel substrate. The process involves vaporizing the coating material (e.g., titanium, zirconium) in a vacuum chamber and depositing it onto the fixture atom by atom. This creates a surface that is incredibly dense and resistant to abrasion, corrosion, and tarnishing. It is the same technology used on high-end watches and architectural hardware, chosen for its ability to retain its luster for decades.

Why PVD is Ideal for Heavy-Use Scenarios

- For a heavy-use faucet coating, PVD offers distinct advantages: Micro-thin and Flexible:The coating is so thin it doesn’t easy crack or peel under stress or temperature fluctuations.

- Consistent Color: the vacuum process ensures color not have too much color different across every batch, which is crucial for large scale projects where are purchased at different installment.

The Economic Argument: Lifecycle Cost Analysis

The initial purchase price represents only a fraction of a faucet’s total cost of ownership. Facilities managers increasingly recognize that specifying premium heavy-use faucet coatings provides substantial long-term savings.

Proving Durability: The Critical Role of Commercial Testing

Manufacturer claims are meaningless without verifiable data. Reputable brands subject their products to grueling commercial durability testing that simulates years of use in a matter of days.

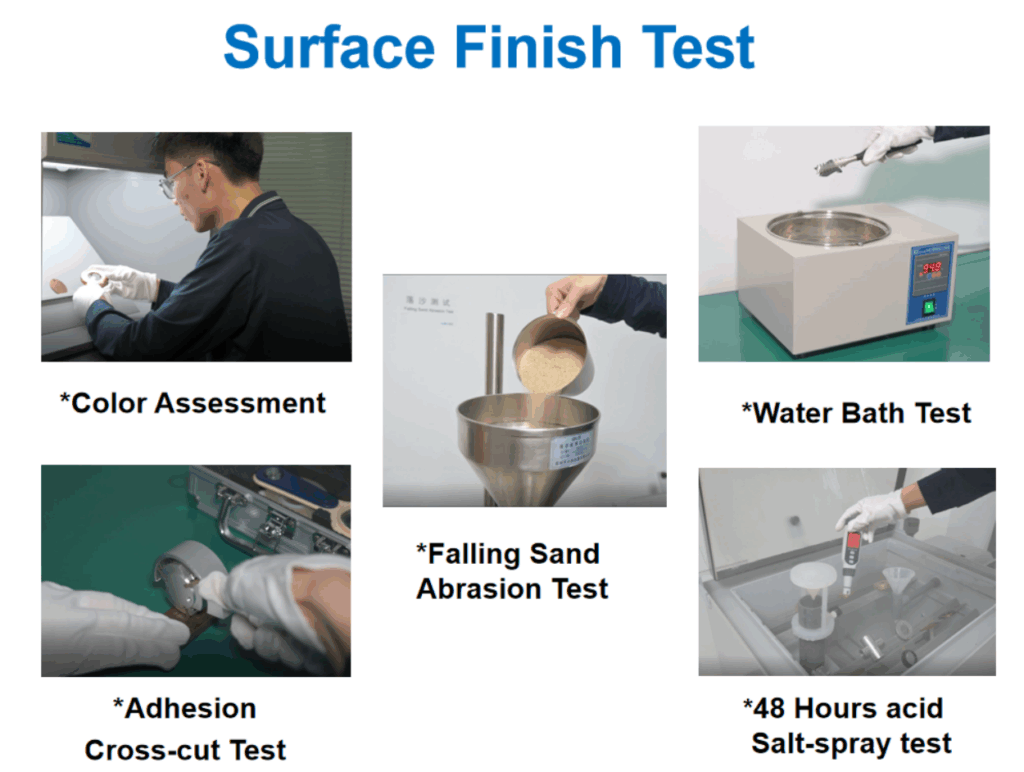

Key Durability Testing Methods

Understanding these tests helps specifiers make informed choices:

- Abrasion and Scratch Testing: Using standardized machines and materials (like cheesecloth or specific abrasive wheels) to simulate millions of wipe-downs and scratches, verifying the scratch-resistant PVD claims.

- Corrosion and Chemical Resistance Testing: Subjecting finishes to salt spray (ASTM B117) and exposure to harsh chemicals to ensure they will not tarnish or degrade in humid, corrosive environments.

- Mechanical Cycle Testing:Automatically cycling the handle and actuation mechanism hundreds of thousands of times to ensure mechanical reliability alongside finish durability.

At Watersino, we don’t just meet these standards; we exceed them. Our internal commercial durability testing protocols are designed to be 50-100% more rigorous than industry norms, ensuring our heavy-use faucet coatings perform flawlessly in the real world.

The Economic Argument: Lifetime Value Over Initial Cost

Specifying the cheapest available faucet for a high-traffic restroom is a costly mistake. The true cost is measured over the fixture’s entire lifecycle.

A low-quality finish will show wear within a year, requiring frequent touch-ups or complete replacement long before the building’s first renovation cycle. This incurs not only the cost of the new hardware but also the high labor costs for installation and the intangible cost of a shabby-looking facility. Investing in a premium scratch-resistant PVD finish on an anti-vandal fixture from the outset virtually eliminates these costs. The finish will last the life of the building, maintaining its appearance and ensuring the facility always projects an image of quality and care. This long-term value is the core of the Watersino promise.

Specify with Confidence for Lasting Performance

For high-traffic restrooms, only the most advanced solutions will suffice. The winning combination is a scratch-resistant PVD finish applied to a robust anti-vandal fixture, backed by verifiable commercial durability testing. This approach guarantees a fixture that will resist wear, abuse, and corrosion, maintaining its aesthetic and functional integrity for years to come.

Choosing anything less is a guarantee of future headaches and unnecessary expense. By partnering with a manufacturer like Watersino that prioritizes engineering and validation, you specify with confidence, knowing your project is equipped with the best heavy-use faucet coatings on the market.

Ready to see the difference true durability makes? Contact Watersino today to request our comprehensive durability testing reports and samples. Let us prove why our finishes are the smartest long-term investment for your next project.

FAQ

With proper care, 10-15 years—far longer than standard finishes.

Not with PVD coatings—they resist stains and require only mild cleaning.

No—PVD must be applied during manufacturing.