This article explores luxury hotel bathroom faucet finish trends and commercial finish warranties. Focus on the durability of PVD coatings on bathroom faucets and ADA-compliant bathroom fixtures.

What are the Core Challenges in Hotel Bathroom Faucet Finishes?

In the hotel industry, bathroom faucets serve not only as functional fixtures but also as key elements of brand image. According to a 2023 report by the American Hotel & Lodging Association (AHLA), faucet and finish replacements account for 35% of the total cost in hotel bathroom renovations. Traditional finishes (such as electroplating) often face three major pain points:

1.Insufficient Durability

In coastal areas, electroplated finishes start corroding within 18 months on average due to high humidity.

2.Design Homogeneity

Common chrome or polished gold finishes struggle to meet high-end customers’ demands for differentiated experiences.

3.Compliance Risks

Non-ADA compliant faucets can lead to legal disputes and brand reputation damage.

What are the Hotel Bathroom Faucet Finishes Trends for Luxury Hotel in 2024?

1. Matte Black and Charcoal Gray: Symbols of Modern Luxury

Matte black and charcoal gray finishes have captured 65% of the high-end hotel renovation market, thanks to their understated luxury. The Marina Bay Sands Hotel in Singapore adopted matte black PVD-coated faucets during its renovation, creating a visually striking modern space when paired with marble countertops.

2. New Interpretations of Metallic Textures: Rose Gold and Champagne Gold

Warm-toned metallic finishes like rose gold and champagne gold are becoming the new favorites of super luxury hotels. The Burj Al Arab in Dubai uses champagne gold PVD-coated faucets in its presidential suite bathrooms, enhancing the luxurious ambiance through light and shadow effects.

3. Minimalist Choices: Satin Nickel and Brushed Chrome

Satin nickel and brushed chrome, with their soft metallic luster, perfectly match minimalist design trends such as Scandinavian and Wabi-Sabi styles. The Aman Resorts in Japan series uses satin nickel PVD-coated faucets, combined with wooden elements, to create a serene and comfortable space.

How durable are PVD-coated faucets?

1. Exceptional Corrosion Resistance

Salt Spray Test Data: PVD coating can withstand over 1000 hours without corrosion, compared to only 500 hours for traditional electroplated chrome (Source: ASTM B117 Standard Test).

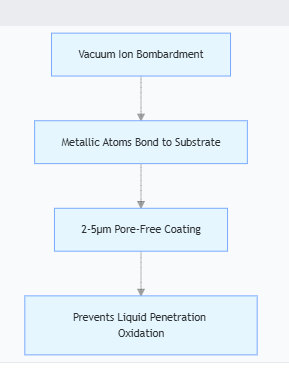

Technical Principle: Through vacuum ion bombardment, metal atoms such as titanium and zirconium form chemical bonds with the substrate. The coating thickness reaches 2-5μm, twice that of traditional electroplated layers.

Laboratory Data: Tested according to the latest ASTM B117-24 standard, PVD titanium-zirconium coating can withstand 1,200 hours of salt spray without corrosion (500 hours for traditional electroplated chrome), equivalent to 15 years of use without renovation in a Miami beach hotel.

Principle Diagram:

2. Superior Abrasion Resistance

A major hotel chain’s test shows that after 100,000 opening and closing cycles, the wear of PVD-coated faucets is only 0.1mm, while traditional electroplated faucets show 0.3mm wear. This means that with 50 daily uses, PVD-coated faucets can maintain their appearance for over 10 years.

Process Breakthrough: The new-generation PVD matte black coating in 2024 incorporates a graphene nanolayer, achieving a scratch resistance rating of 6H (3H for traditional matte black). The new wing of Atlantis The Palm Dubai uses this technology, showing no discoloration after 2 years of seawater moisture testing.

Scratch Resistance Test Results

| Coating Type | Scratch Resistance | 2-Year Seawater Test |

| Traditional Matte Black | 3H | Discoloration |

| PVD Matte Black + Graphene | 6H | No Change |

3. Adaptability to Extreme Environments

- Temperature Resistance: From -20°C to 200°C, preventing coating peeling caused by hot water

- Chemical Resistance: Achieves the highest level 5 resistance to common chemicals like shampoos and shower gels.

What are the ADA-compliant bathroom fixtures Requirements for Hotel Faucets?

Popular Finishes for Commercial Bathrooms

According to the Americans with Disabilities Act (ADA), hotel bathroom faucets must meet the following standards:

1.Operation Force Limit

The handle operation force should not exceed 5 lbs (approx. 2.27kg). PVD-coated faucets typically maintain an operation force of 3 lbs or less through optimized valve core designs.

2.Space Requirement

Protrusion from the wall should be ≤4 inches (approx. 10.16cm) to avoid collisions with wheelchair users.

3.Anti-Slip Design

PVD coating can increase friction by 40% in wet conditions through surface texturing.

How Do Commercial Finish Warranties Protect Hotel Investments?

Marriott International Group’s global procurement requires PVD faucets to provide a 10-year commercial warranty, and the comprehensive holding cost is reduced by 45% in 10 years.

| Finish Type | Traditional Electroplating | PVD Coating (Commercial Grade) |

| Warranty Period | 1-2 years | 5-10 years |

| Coverage | Non-human-induced fading | Fading, peeling, corrosion |

| Service Support | Self-paid repair | Free on-site replacement |

Watersino: Your trusted PVD hotel faucet partner

Watersino focuses on high-end PVD-plated faucets, providing luxury hotels, resorts and commercial projects with

- Extreme durability – corrosion-resistant and scratch-resistant, perfect for high-traffic environments.

- Luxury aesthetics – matte black, rose gold, champagne gold, brushed nickel and other colors are available

- ADA-compliant design – taking into account both accessibility and design aesthetics

- 10-year commercial warranty – providing long-term protection for hotel operators.

Three reasons to choose Watersino

- Customized solutions – tailored to the hotel brand tone.

- Global supply chain – supports the efficient delivery of large-scale hotel projects.

- Sustainable economy – reduce replacement costs and enhance guest experience.

Contact us now to learn how Watersino PVD faucets can upgrade your hotel!

In an era where hotel design emphasizes differentiation and sustainability, PVD coating stands out as the ideal choice for high-end hotel faucets due to its outstanding durability, diverse finish options, and comprehensive after-sales support. Whether it’s addressing corrosion challenges in coastal environments or meeting ADA compliance requirements, PVD coating demonstrates unparalleled advantages.

If you are planning a hotel bathroom renovation project, feel free to share your needs and questions in the comments section. Alternatively, contact our professional consulting team for customized solutions.

FAQ

Is PVD coating suitable for all types of hotels?

Yes, PVD coating is especially suitable for high-end hotels, coastal hotels, and high-traffic scenarios, effectively reducing maintenance costs and enhancing brand image.

How can I determine if a faucet meets ADA standards?

It is recommended to choose products certified by ICC-ES (International Code Council Evaluation Service) to ensure full compliance.