The faucet supply chain risks are a major concern for businesses sourcing high-quality fixtures. This article examines faucet quality control, faucet manufacturing risks, and how to identify a non-compliant faucet supplier. By analyzing industry standards and supplier evaluation methods, we highlight key pitfalls and solutions. Understanding these risks ensures better procurement decisions, reduces costs, and enhances product reliability.

Understanding Faucet Supply Chain Risks

The global faucet industry is highly dependent on a complex supply chain involving raw material sourcing, manufacturing, logistics, and compliance checks. Faucet supply chain risks can disrupt operations, increase costs, and damage brand reputation if not managed properly.

Key Risk Factors in Faucet Supply Chains :

1.1 Material Shortages & Price Volatility

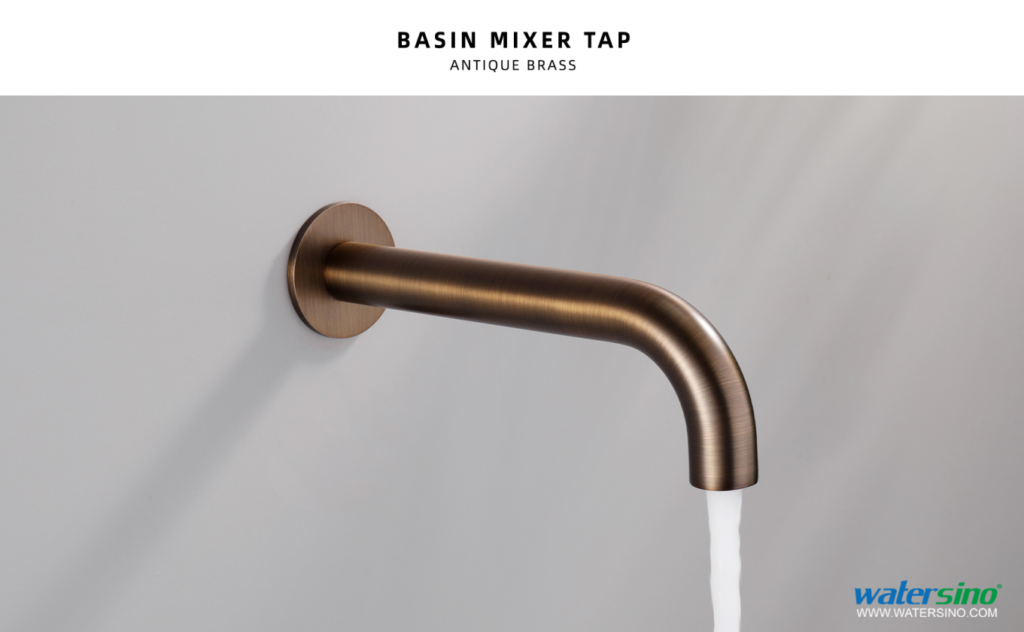

Brass, zinc, and ceramic cartridges are essential components, and their fluctuating prices can impact production costs.

Geopolitical tensions or trade restrictions may delay material procurement.

1.2 Inconsistent Quality Control

Poor faucet quality control leads to leaks, corrosion, or mechanical failures. Substandard materials (e.g., low-grade brass) reduce product lifespan.

1.3 Regulatory Non-Compliance

Non-compliant faucet suppliers may ignore lead-free (LF) or Water Efficiency (WELS) standards. Failing to meet NSF/ANSI 61 or WRAS certifications can result in legal penalties.

1.4 Logistical Delays & Supplier Reliability

Shipping bottlenecks, port congestion, or supplier insolvency can halt production.

How to Mitigate These Risks?

- Diversify suppliers to avoid dependency on a single source.

- Conduct regular audits to verify material quality and compliance.

- Work with certified manufacturers like Watersino, ensuring adherence to global standards.

1.5 Unreliable Faucet Manufacturing Practices

Some faucet manufacturers cut costs by using substandard materials (e.g., low-grade brass) or skipping durability tests

Key risks:

Lead contamination in non-compliant faucets.

Poor valve mechanisms causing leaks.

Solution:

Audit suppliers’ material sourcing and production processes.

Prioritize brands with strong faucet quality ratings.

Identifying a Non-Compliant Faucet Supplier

A non-compliant faucet supplier may offer attractive pricing but often compromises on safety and durability. Recognizing red flags early can save businesses from costly recalls or reputational damage.

Warning Signs of a Risky Supplier

- Lack of Certifications : Reputable suppliers hold NSF, WRAS, or ISO 9001 certifications. Avoid those unable to provide compliance documentation.

- Poor Faucet Quality Ratings : Check third-party reviews, industry benchmarks, and customer feedback. Frequent complaints about leaks or finish defects indicate poor manufacturing.

- Unclear Material Sourcing : Ethical suppliers disclose brass composition (lead-free vs. low-cost alternatives). Be wary of vague responses about material origins.

- Unstable Production Capacity : Suppliers with frequent stockouts or delayed shipments may lack proper infrastructure.

Why Choose Certified Suppliers Like Watersino?

Watersino stands out as your trusted partner with comprehensive ISO 9001, 14001, and 45001 certifications, ensuring top-tier quality, environmental responsibility, and workplace safety. Our products meet global compliance standards, including WATERMARK(1000+) & SAA for Oceania, WRAS for the UK, CE/ACS for Europe, and UPC/WaterSense for North America, guaranteeing seamless market access. We offer full OEM/ODM services with free customization—from product design to packaging, laser-engraved logos, and certification labeling. Backed by industry-leading warranties (7-year main product, 5-year accessory) and durable PVD-coated (3-year) and water/paint-resistant (1-year) finishes, we deliver reliable, long-lasting solutions tailored to your brand’s needs. Choose Watersino for certified quality, regulatory compliance, and unmatched manufacturing expertise.

Guaranteed compliance with international safety standards. Transparent sourcing of high-grade materials. Consistent quality control through automated testing.

Mitigating Faucet Manufacturing Risks

Implementing strategic measures is essential to minimize potential risks in faucet manufacturing.

Dual-Sourcing Strategy : Adopt a dual-sourcing strategy by establishing partnerships with 2-3 qualified suppliers for critical components like cartridges and valves. This approach ensures continuity of supply if one vendor encounters issues.

- Contractual Safeguards: Incorporate contractual safeguards that clearly define quality expectations and impose financial penalties for defective product batches or delivery delays. These clauses provide legal protection and incentivize compliance.

- Digital Supply Chain Monitoring : Ieverage digital supply chain monitoring through advanced ERP systems that provide real-time visibility into production progress, inventory levels, and quality control metrics. This enables prompt issue identification and resolution.

- Collaborate with OEM Experts : Collaborate with established OEM specialists like Watersino who offer comprehensive risk management solutions. Their expertise in end-to-end manufacturing processes, from material selection to final inspection, significantly reduces quality and delivery risks while ensuring regulatory compliance throughout the production cycle.

Choosing the Right Faucet Supplier

Supplier Selection Checklist

- Certifications: Verify all necessary certifications including NSF for water safety, WRAS for UK/EU compliance, and ISO 9001 for quality management systems. These credentials demonstrate the supplier’s commitment to meeting international standards.

- Quality Ratings: Examine independent lab test reports from recognized third-party organizations like SGS or Intertek, which provide objective evidence of product durability and performance.

- Production Capacity: Production capacity is another vital consideration – look for suppliers capable of manufacturing steady to ensure they can scale with your business needs and handle peak demand periods without delays. This production volume also typically indicates established manufacturing infrastructure and experience.

- fter-Sales Support: Equally important is evaluating the supplier’s after-sales support offerings. A robust warranty program shows confidence in product longevity and protects your business from unexpected repair costs. Additional support services like technical assistance, replacement part availability, and responsive customer service should also be considered when making your final decision.

Ensures products meet strict international quality, safety and environmental standards

Ensuring Proper Faucet Quality Control

Strong faucet quality control processes are essential for reliable products. Key steps include:

- Regular factory audits to inspect production standards

- Third-party testing for lead content and water efficiency

- Tracking faucet quality ratings from industry benchmarks

Brands that skip these measures risk selling faulty faucets, damaging their reputation.

Managing faucet supply chain risks requires due diligence in supplier selection and faucet quality control. By avoiding non-compliant faucet suppliers Watersino combines global certifications, customized manufacturing solutions and exceptional product quality to deliver reliable, market-ready products worldwide. Our comprehensive approach ensures your brand gets premium products with complete regulatory compliance and outstanding durability.

Ready to secure a reliable faucet supply chain? [Contact Watersino]for certified, high-quality fixtures backed by rigorous testing.

6.FAQ

Certifications:Check for industry standards like ISO 9001, NSF/ANSI 61, WRAS, or CE for quality and safety.

Audits & Reports:Request third-party inspection reports or factory audit records (e.g., SGS, BV).

Legal Compliance: Ensure they meet local regulations (e.g., lead-free requirements in the U.S. per AB 1953/NSF 372).

Customer Reviews: Look for verified feedback on platforms like Google

Yes, Watersino Flexible MOQ, accept trial order. Contact them directly for MOQ (Minimum Order Quantity) details.

Yes,watersino offer free laser engraving of your trademark/logo on the products. This includes precise and permanent marking without additional costs. Please provide your logo design file (vector format preferred) for confirmation before production